3d printing brisbane

John Chambers, Executive Chairman of Cisco System, tells us that at least 40% of all businesses will fail in the next ten years unless they can figure out how to change their entire company to accommodate new technologies.

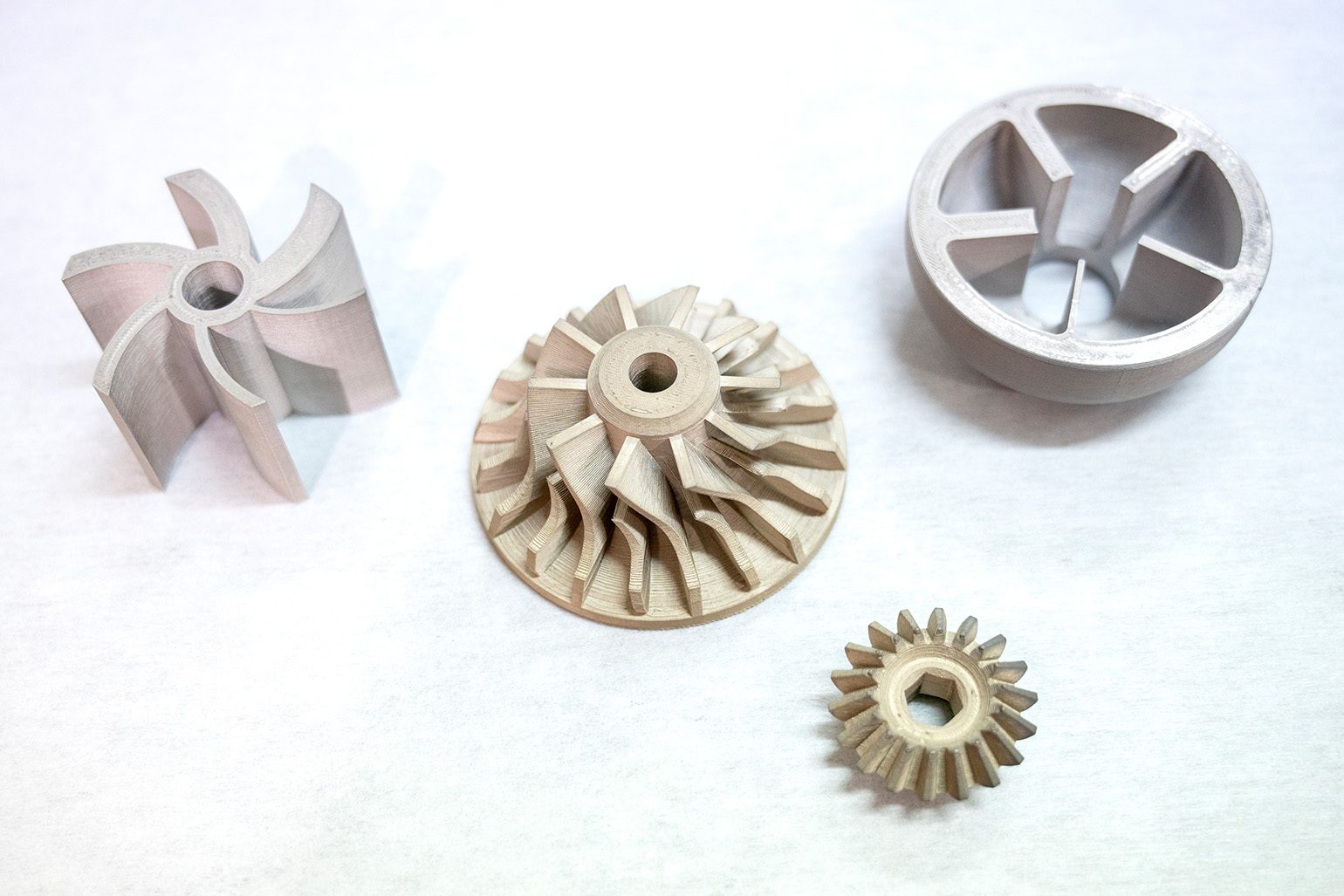

3D Printing is that new technology, and it is a game-changer in spare parts production. 3D Printing revolutionises the manufacture,

storage, and shipping of spare parts and solves many problems for Asset Intensive industries with machinery and equipment that needs to

be maintained. With 3D Printing technology, manufacturers and producers don't have to rely on external spare part manufacturers

supplies. However, even if a manufacturer chooses to work with an external spare parts supplier, the process will be more seamless and

timely.

The goal of 3D Printing is to produce on-demand spare parts as opposed to making and storing parts. Companies reduce their costs by eliminating the need to keep spare parts.

To produce 85,000 fuel nozzles for their Leap Jet Engines

This home appliance manufacture started 3D Printing, reducing their need to stockpile spare parts for their appliances

Some Porsche vehicles are now old, and the production of spare parts for these older cars is now non-existent, so the Porsche Classic division set up 3D Printing to produce spare parts for their rare vehicles. The first 3D Printing part was a clutch release lever for their Porsche 959.

Jaguar used 3D Scanning to reproduce the classic XKSS 1957 model. The entire recreation took Jaguar 18 months to complete.

This company implemented 3D Printing for their tooling process. They also recreated the iconic 1962 Microbus

The Bentley Speed 6 on a 3D Printer created grille, side air vents, door handles and exhaust on this late model.

Recently Ford printed its 500,000th part, which was an engine cover for its Ford Mustang. Interestingly they reported that traditional methods would take four months and $500,000, but with the 3D Printing technology, the same process took four days and cost $3,000.

Aerospace engineers have taken to 3D printing inspection tooling to reduce costs for low-volume parts.

Boeing has manufactured 20,000 parts for its military and commercial planes. The 787 Dreamliner has 30 printed parts, including air ducts and hinges.

The Nike Vapor Laser shoe has 3D Printed plate and cleats.

edag light cocoon

EDAG's Light Cocoon is a concept car made by the independent automotive developer EDAG, which boasts a 3D printed branch-like load-bearing structure inspired by nature. Although design uses less material than a standard chassis, all requirements are met on structurally relevant components. The chassis body panels are fabric covered to protect them from the elements.

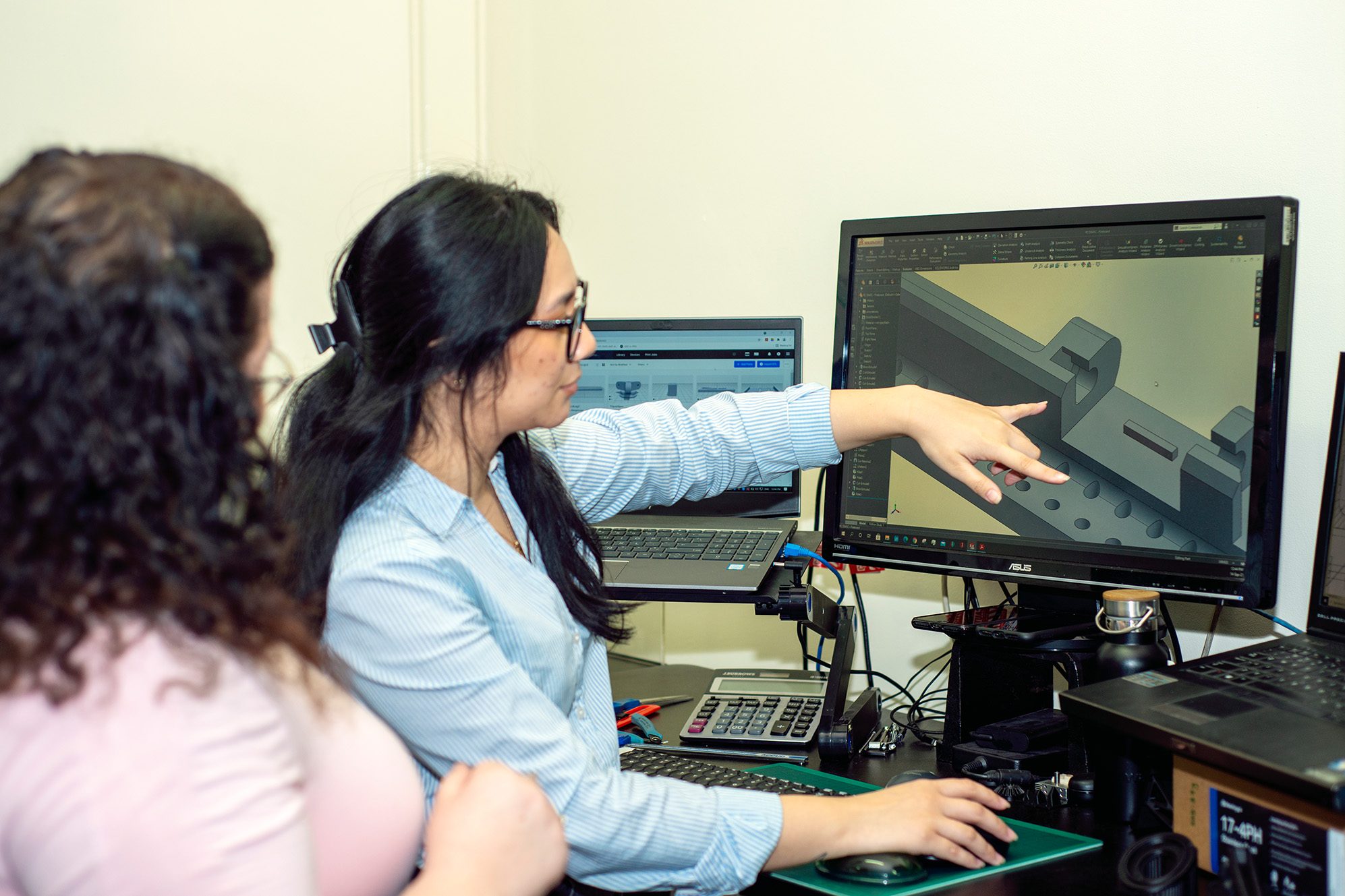

Conceptually having a tangible object can help you through the creative process. Retrocast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to Retrocast 3D Printing to explore your

options and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More