WHAT IS

3D Printing is a new technology that is the future of modern manufacturing. The transformative impact on many industries is unimaginable. The fact that 3D Printing can produce a spare part in days, not months, will return a positive return on investment to many sectors. This process provides the opportunity for organisations to quote for more work, turnover more products, and positively impact their bottom line. 3D Printing was widely known as additive manufacturing, is becoming industry prominent, and it is surprising to note that the technology has been around for about thirty years.

Why is 3D Printing useful?

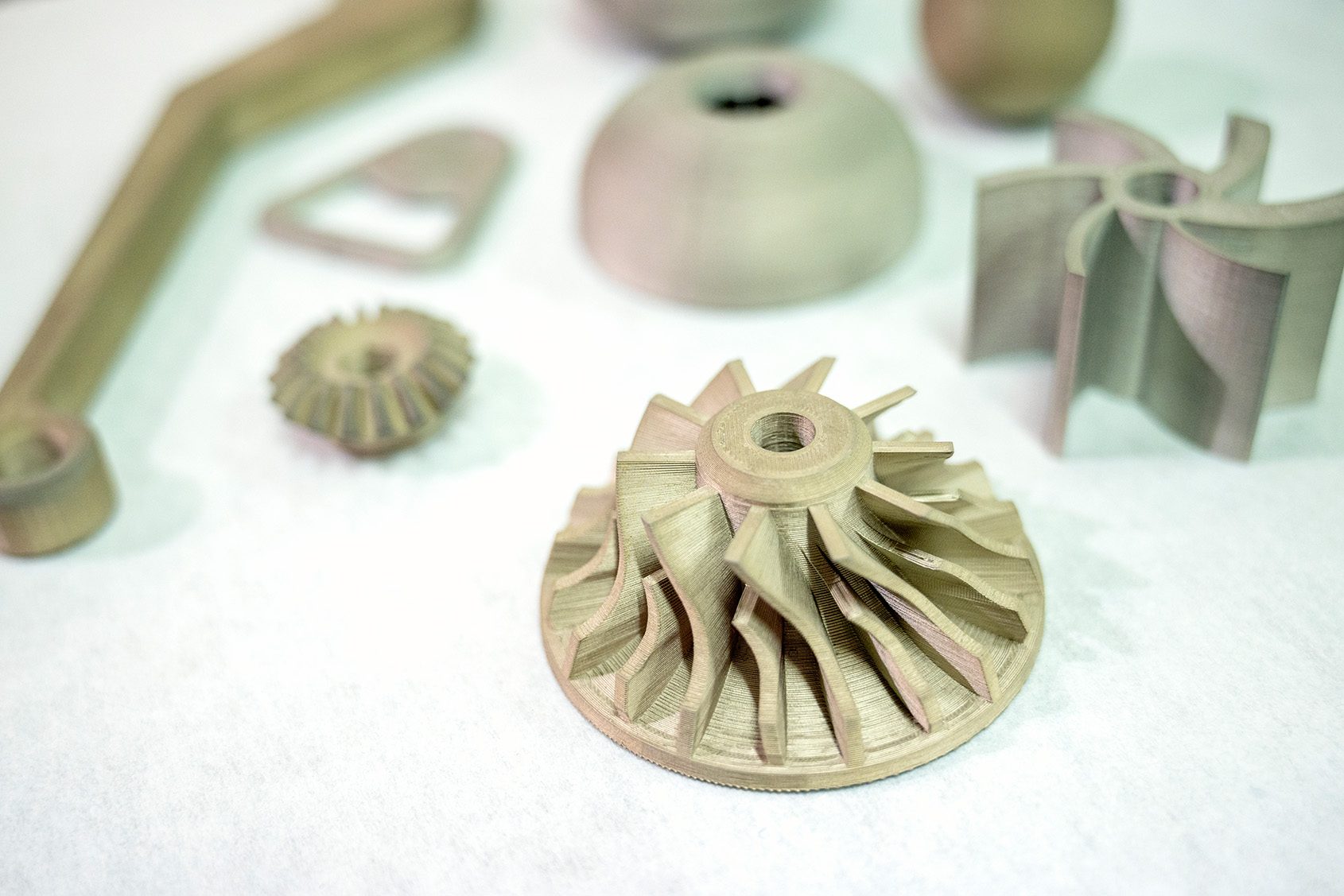

Additive manufacturing has a wide range of prospects, including universities, medical, airlines, aerospace, automotive, and the

manufacturing industry, all focusing their energies on 3D Printing capabilities.

Polymers, resin and metal.

ABOUT

Iterative – Create a prototype from the product design, test it for functionality, design a new iteration and manufacture the new prototype for testing. The old iteration is then, and the old version is obsolete. This type of industrial Prototyping can be time consuming and expensive.

Parallel – This is used when several design

concepts are compared concurrently. Multiple designs are drafted and then compared to find the best versions before a physical prototype

is 3D printed. This method can be costly due to the number of prototypes to create one product.

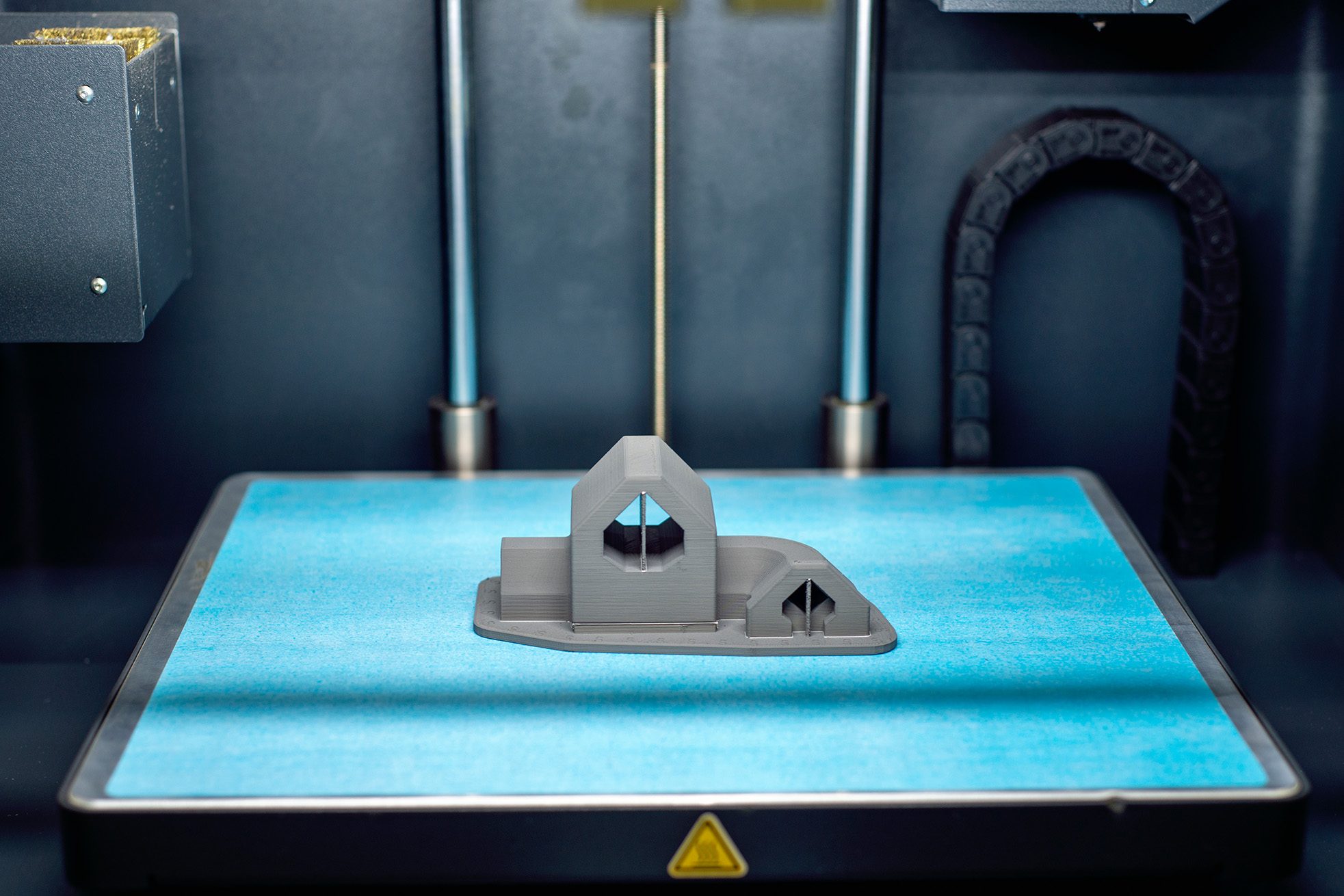

Rapid -Rapid Prototyping is our preferred model. It incorporates some

aspects of the iterative process. This method is fast and accessible for product designers who can access CAD software and 3D Printing,

and Retrocast 3D Printing has the equipment. An advantage of this method is it is an affordable way to run usability and

functionality tests on newly printed mockups.

why use

The significant advantage of using rapid Prototyping is the efficiency of the design, manufacture, and ability to test your prototype within minimal time. Not only is your downtime minimal your costs are also reduced.

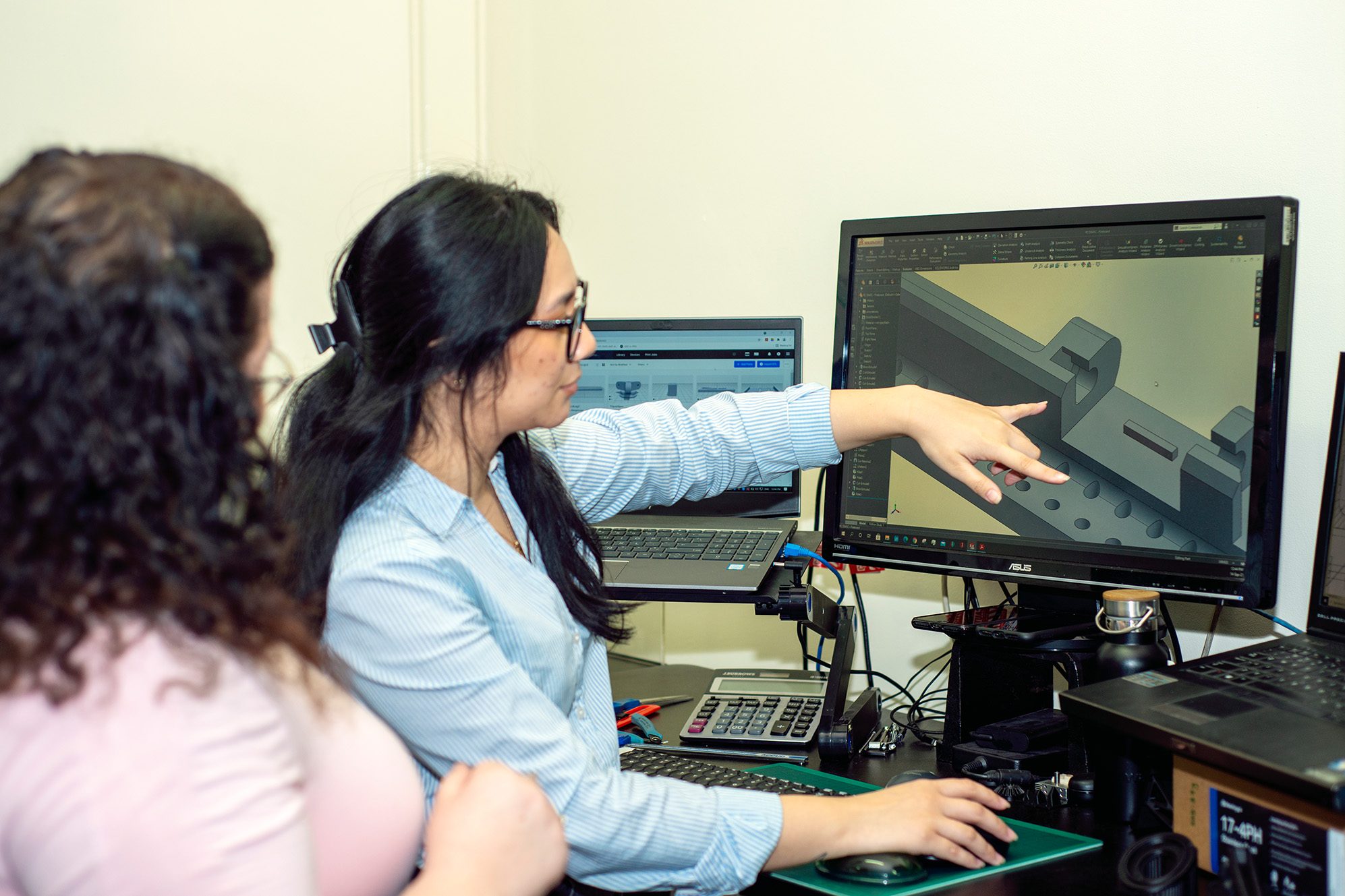

exploring

Technology has enabled us through our CAD system to highlight discrepancies between your design and manufacture or components by overlaying the original CAD file to the 3D Prototyping eliminating redevelopment costs and cycle time. 3D Prototyping is the wave of the future for innovators and Entrepreneurs.

Talk to our Engineering team today to discuss your idea - Talk to Retrocast 3D Printing, about your project today. Call us on 07 3348 5057

Conceptually having a tangible object can help you through the creative process. Retrocast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

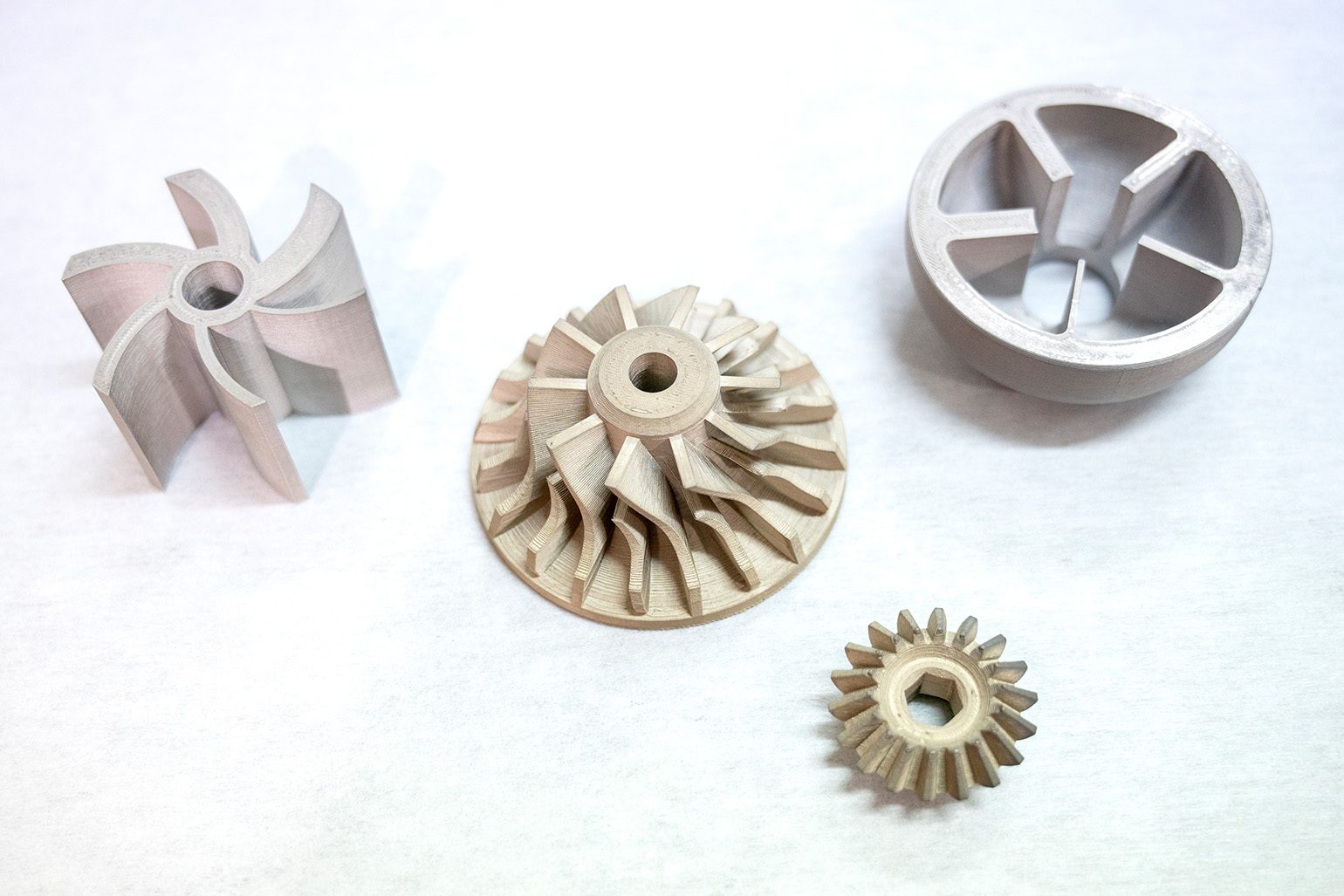

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to Retrocast 3D Printing to explore your

options and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More