REVOLUTIONARY

In recent years, 3D printing has undergone a rapid and astonishing evolution, reshaping manufacturing as we know it. This groundbreaking technology's ability to craft intricate objects layer by layer has revolutionized traditional manufacturing processes. As we enter the last half of 2023, it's an opportune moment to delve into the significant impact 3D printing has had on the manufacturing industry.

It's a perfect time to reflect on the profound influence this technology has had on the manufacturing sector, and to envision the exciting possibilities that lie ahead.

RETROCAST 3d Printing

.jpg)

The agriculture industry's embrace of 3D printing may surprise some, but it's a testament to the technology's adaptability and efficiency. Manufacturers like John Deere, while not yet using 3D printing for end-use parts, are actively exploring its potential. The company's success with tooling, where over 40 printers fabricate tools for their factories, demonstrates the technology's value.

Caterpillar, A player in both heavy equipment and agriculture, is also dipping its toes into 3D printing. With less than 100 3D-printed parts in production, Caterpillar is making strides in additive manufacturing. It's a clear sign of the industry's slow but steady move toward adopting 3D printing.

We are proud to be ISO 9001 Certified for Quality Assurance. We consistently review our systems, processes and products to ensure continuity and progress to ensure customer satisfaction and maintaining industry standards for quality.

3D PRINTING BRISBANE

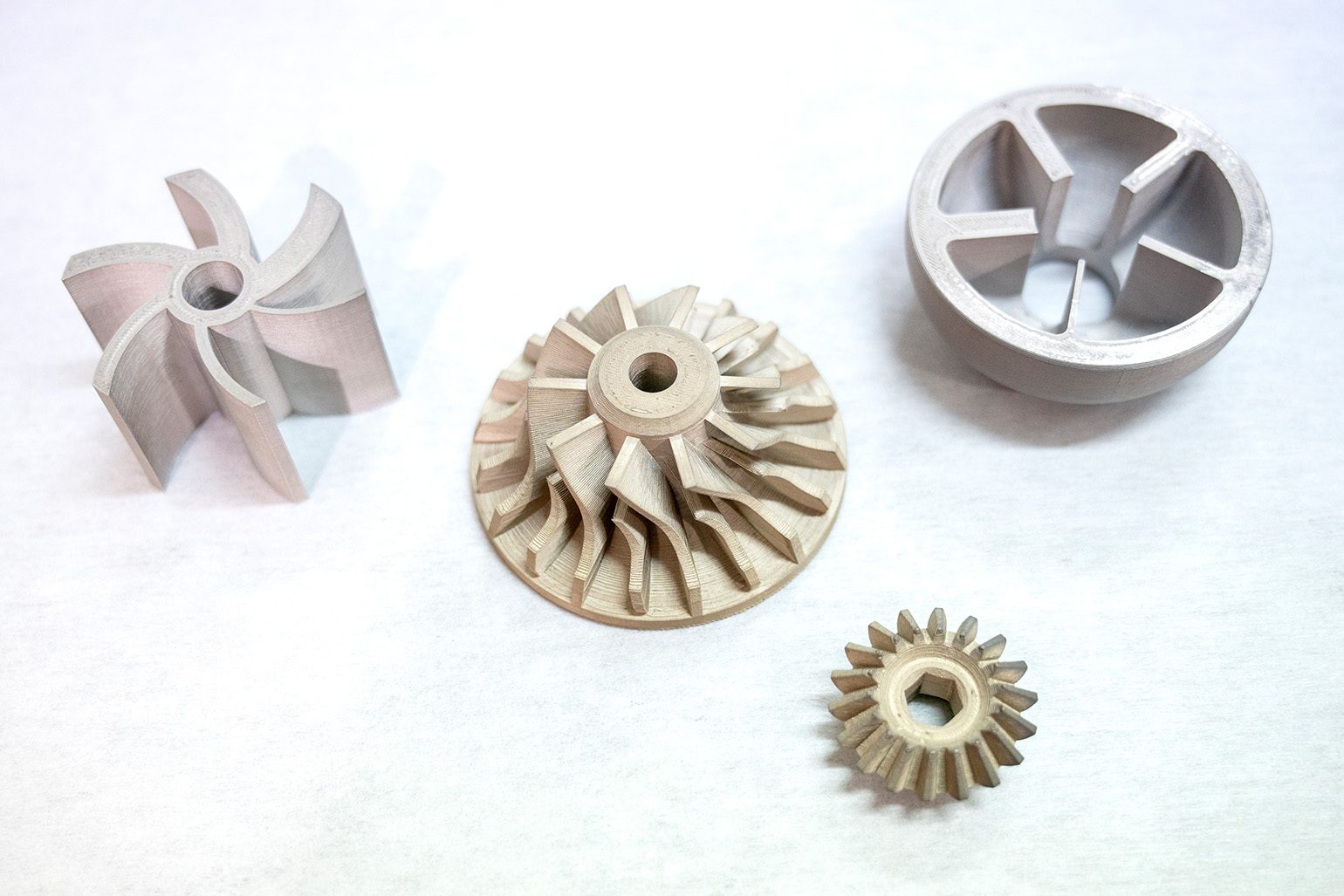

Prototyping: Agricultural equipment design and prototyping benefit immensely from 3D printing. Custom parts and components can be rapidly developed and tested, reducing time-to-market for new products. Customisation: 3D printing enables the customisation of agricultural equipment and machinery, catering to the specific needs of farmers. This level of personalisation can significantly enhance productivity and efficiency. Spare Parts Production: Retrocast, like CNH Industrial, is exploring 3D printing for the production of spare parts. This development can potentially revolutionise agriculture maintenance and repair processes, reducing downtime and costs.

While 3D printing holds immense promise for agriculture, it also faces challenges. John Deere's controversial stance on equipment repairs and software locks highlights a potential hurdle in the industry's adoption of 3D printing for spare parts. However, the drive for innovation and cost savings will continue to push the boundaries of 3D printing.

The agricultural industry's shift toward 3D printing is indicative of the broader trend of technology's integration into traditional sectors. Brisbane's Retrocast 3D Printing and global players like John Deere, Caterpillar, and CNH Industrial are at the forefront of this transformation. As 3D printing technology advances and is more accessible, we can expect further innovations that will enhance productivity, reduce environmental impact, and improve the sustainability of agriculture, ultimately benefiting farmers and consumers alike.

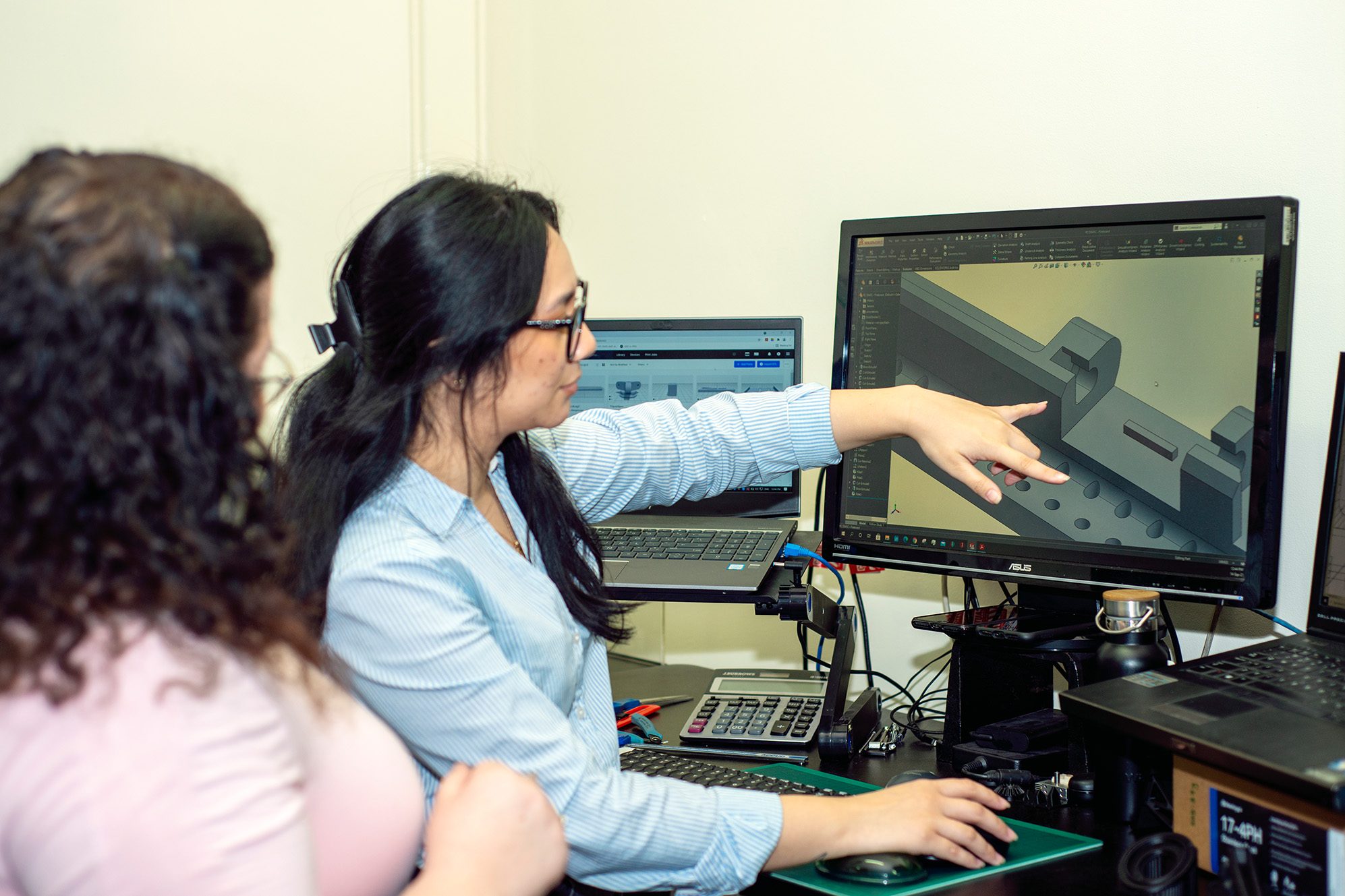

RetroCast 3D Printing provides end-to-end 3D Printing Services located here in Brisbane QLD. We can assist in the design, production, and testing of your project and its application. Call or email us today.

Conceptually having a tangible object can help you through the creative process. RetroCast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to RetroCast 3D Printing to explore your options

and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More

Enter your content here