introDUCTION

What is Metal 3D Printing?

Metal 3D printing is a technology that uses additive manufacturing to produce metal parts by layering metal powder and fusing it using a

laser or electron beam. Metal 3D printing is also known as additive manufacturing - a process of creating three-dimensional objects by

adding material layer by layer, rather than subtracting material through machining or moulding processes.

How Does Metal 3D Printing Work?

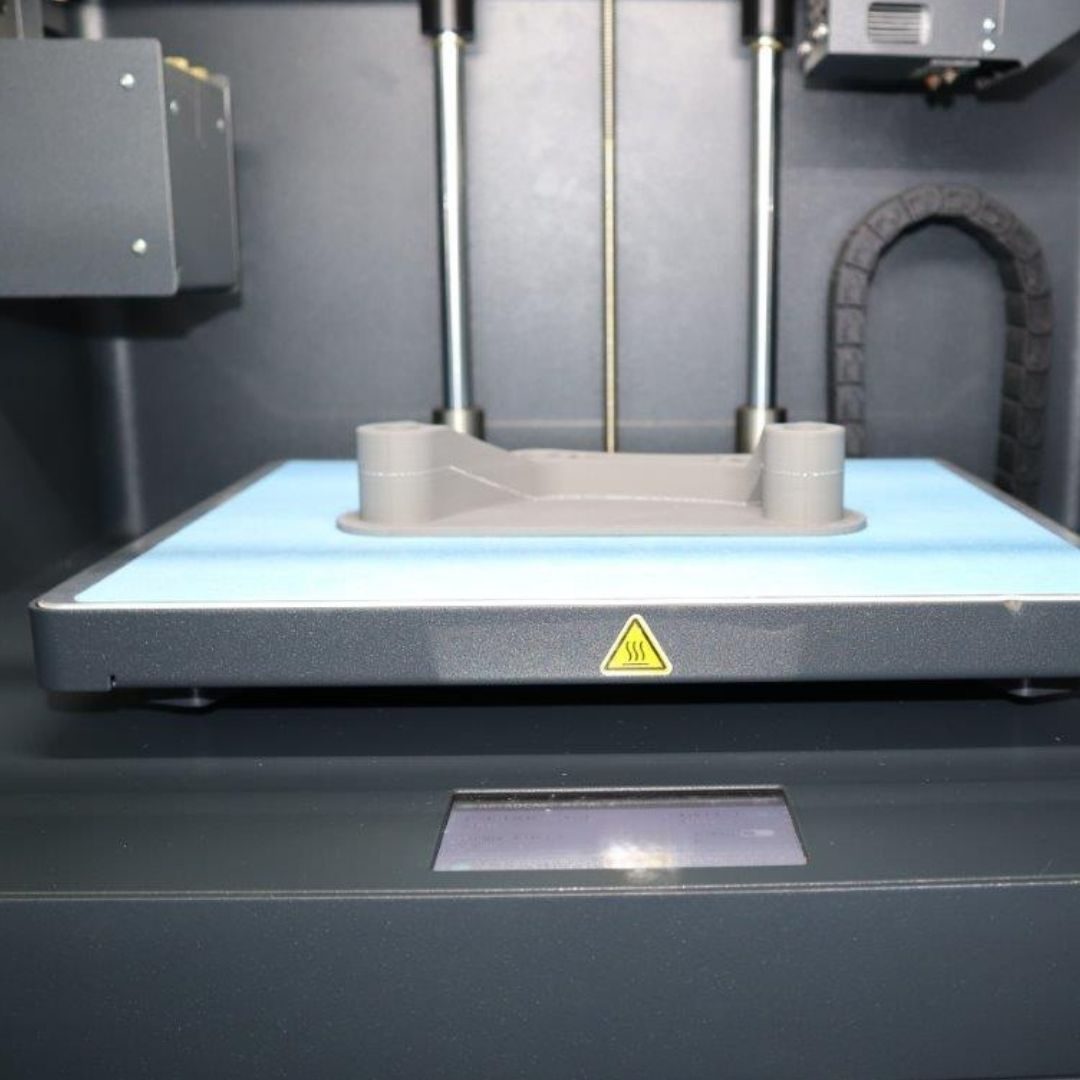

The metal powder is spread layer by layer using a roller or similar mechanism, and a laser is used to selectively melt the powder to form the desired shape. This process continues layer by layer - until the entire part is complete. The result is a metal part with complex geometries and high precision that can be used for various applications.

At Retrocast 3D Printing we take pride in our processes and dedication to providing high quality products and maintaining thorough testing processes to ensure customer satisfaction and premium product and service delivery.

INDUSTRIAL APPLICATIONS

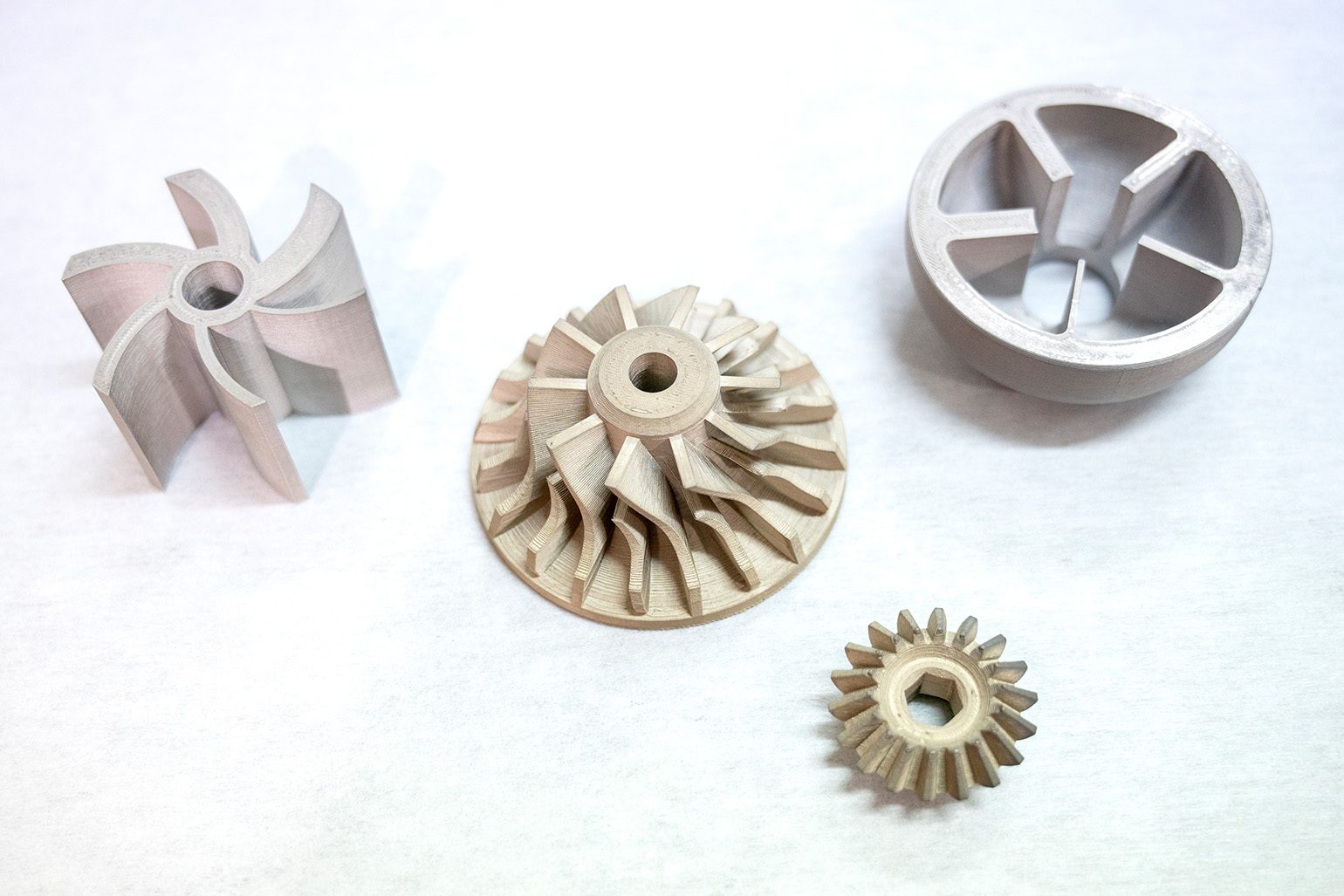

Metal 3D printing is particularly useful in the aerospace, automotive, medical, and tooling industries. It allows for the production of high-quality parts with high strength, good mechanical properties, and excellent accuracy. Metal 3D Printing can be implemented in the following industries:

Metal 3D printing is a versatile technology that offers a high level of precision and flexibility, making it suitable for a wide range of applications across various industries.

We are proud to be ISO 9001 Certified for Quality Assurance. We consistently review our systems, processes and products to ensure continuity and progress to ensure customer satisfaction and maintaining industry standards for quality.

INDUSTRIAL APPLICATIONS

Metal 3D printing can be useful in agricultural machinery and engineering for a variety of applications, including the following:

Overall, metal 3D printing can provide significant benefits to the agricultural machinery industry by enabling the creation of customized, high-performance parts and improving the efficiency of the manufacturing process. By leveraging this technology, agricultural machinery manufacturers can create innovative products that are more reliable, efficient, and cost-effective.

Retrocast 3D Printing provides end-to-end Metal 3D Printing Services located here in Brisbane QLD. We can assist in the design, production, and testing of your project and its application. Call or email us today.

Using metal 3D printing solutions, engineers can create sustainable, efficient, and cost-effective solutions for their operations. However, there are some challenges associated with implementing this technology in agriculture. These include the cost of materials, the complexity of 3D printing processes, and the need to know how to use this technology in an agricultural context. Retrocast 3D Printing can help you with designing and testing the prototypes for feasibility and durability. With these challenges in mind, it is essential to explore strategies to overcome them so that metal 3D printing can be widely used in agriculture. Talk to our team of engineers today.

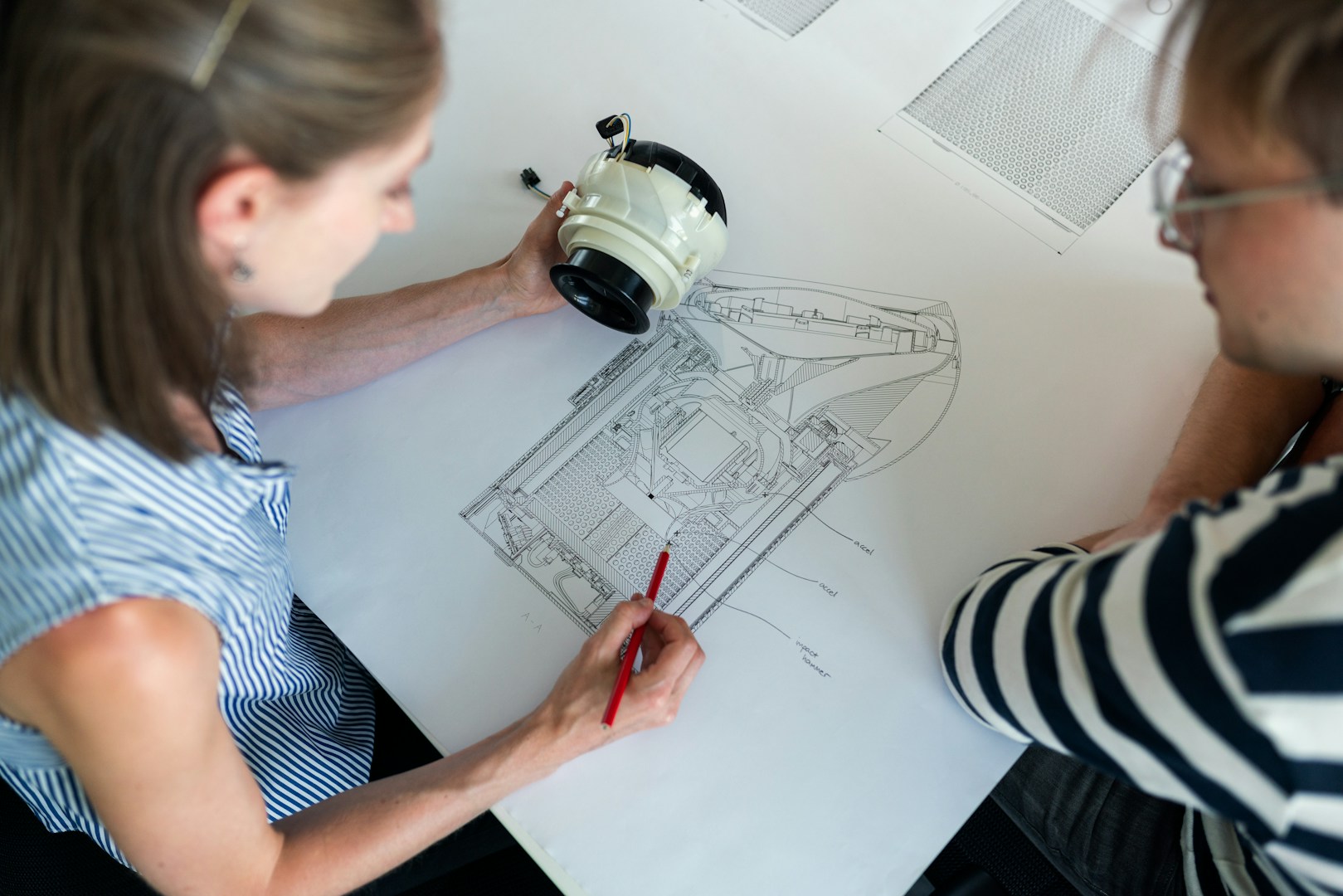

Conceptually having a tangible object can help you through the creative process. Retrocast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to Retrocast 3D Printing to explore your

options and get a quote.

Get a Quote

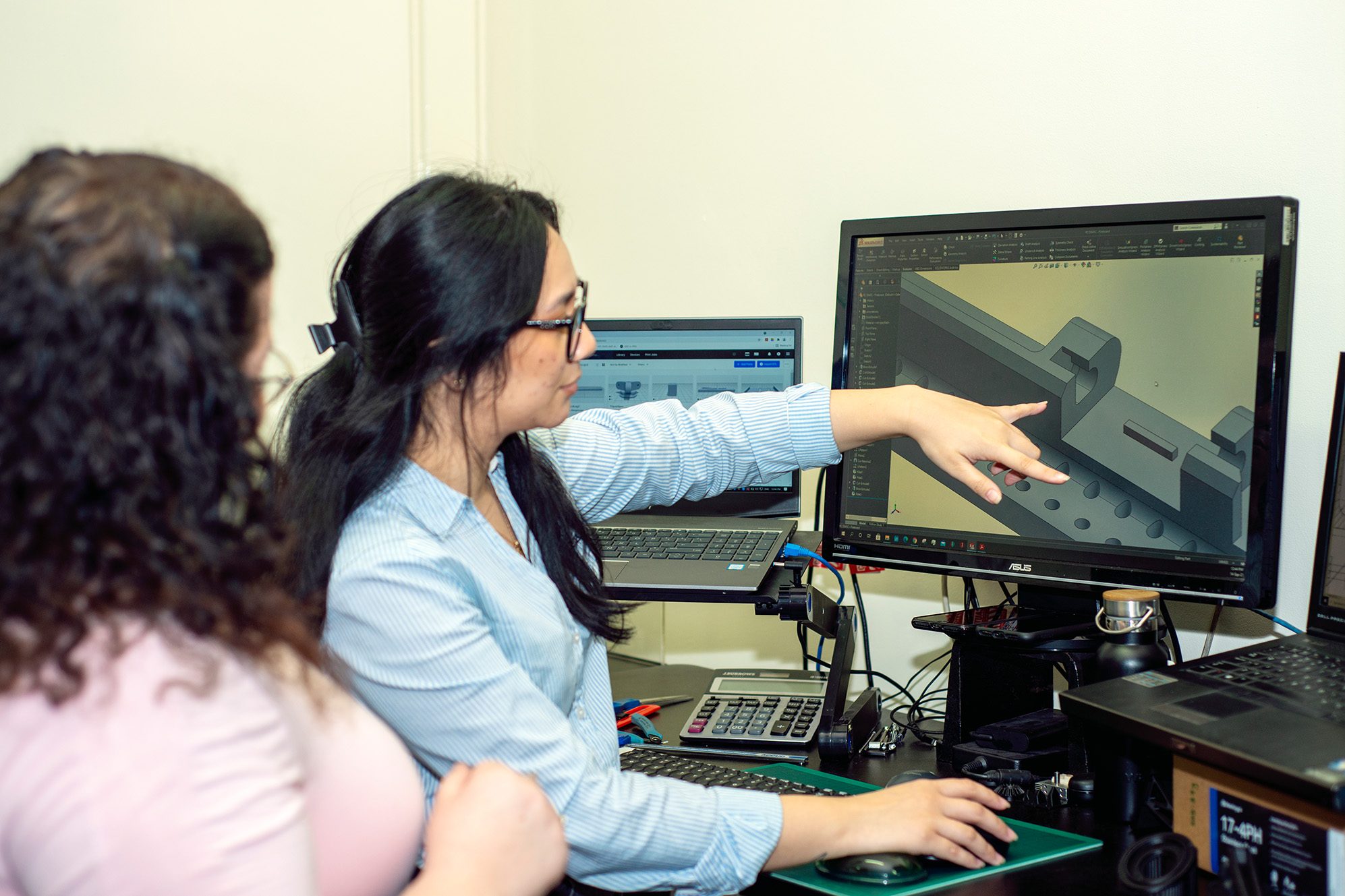

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More