REVOLUTIONARY

In recent years, 3D printing technology has rapidly evolved, transforming the manufacturing landscape in unimaginable ways. With its ability

to create complex objects layer by layer, 3D printing has revolutionised traditional manufacturing processes.

As we enter the last six months of 2023, it's worth exploring the significant impact this groundbreaking technology has had on the manufacturing industry.

RETROCAST 3d Printing

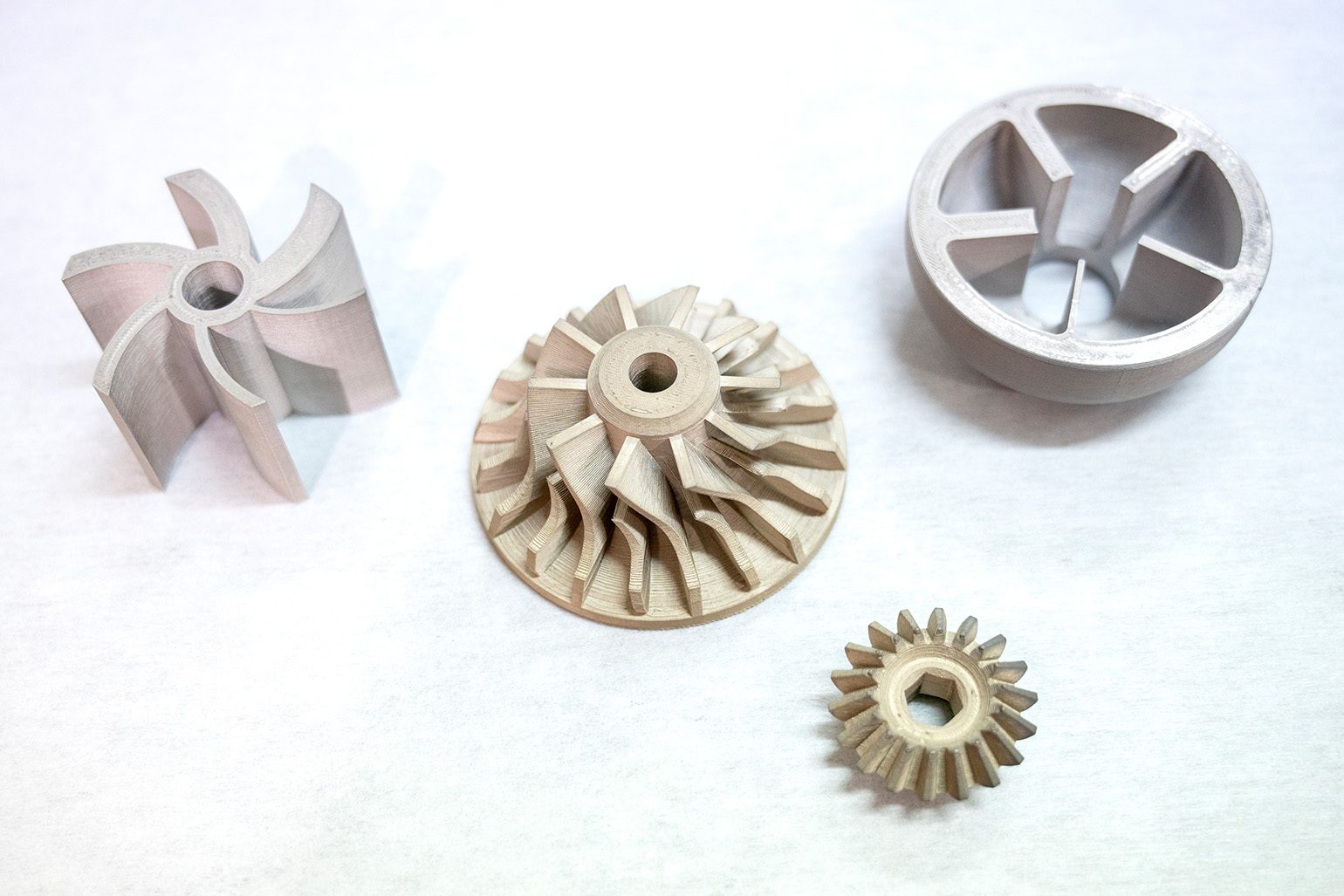

One of the most remarkable advancements of 3D printing is its influence on product development and prototyping. Manufacturers can now bring their concepts to life quicker than ever before. The technology allows for creating intricate and precise prototypes, facilitating faster iterations and reducing the time required to bring a product to market.

With 3D printing, companies can identify design flaws and make necessary adjustments at an early stage, resulting in cost savings and

improved product quality.

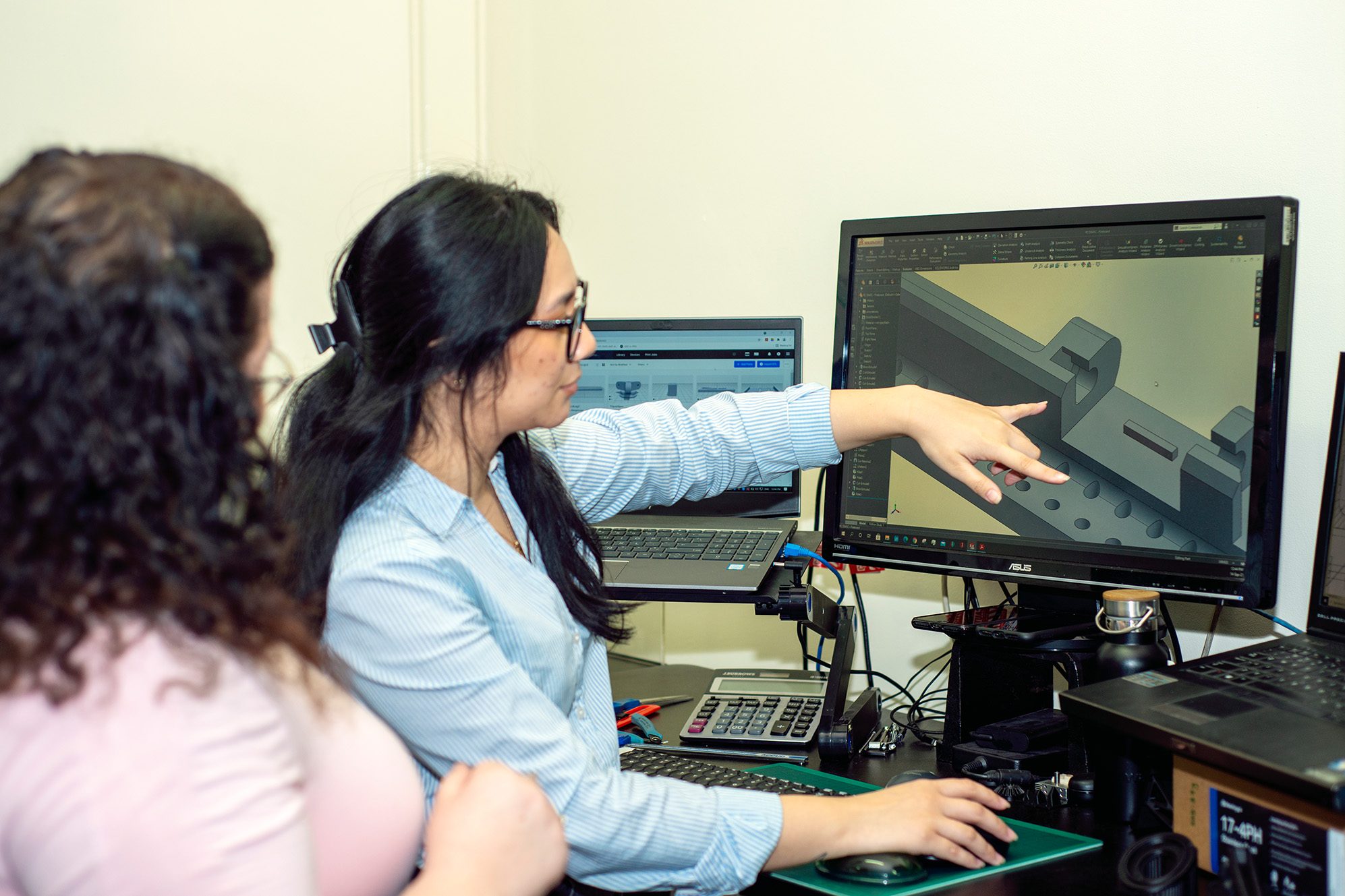

RetroCast 3D Printing is the best in Brisbane. Our expertise and commitment to customer satisfaction make them the ideal partner for all

your 3D printing and Part Manufacturing. Simply bring us the part specifications and we can print in the material of your choice.

We are proud to be ISO 9001 Certified for Quality Assurance. We consistently review our systems, processes and products to ensure continuity and progress to ensure customer satisfaction and maintaining industry standards for quality.

3D PRINTING BRISBANE

Another significant impact of 3D printing on the manufacturing industry is its ability to enable customisation and personalisation on a mass scale.

Traditional manufacturing techniques often need help to meet the demands of consumers seeking unique products. However, 3D printing empowers manufacturers to produce customisable items tailored to individual preferences. This level of customisation satisfies consumer desires and opens up new business opportunities, allowing companies to offer personalised products at scale.

Reduced Costs and Increased Efficiency The cost-saving potential of 3D printing is undeniable. Manufacturers can significantly reduce production costs by eliminating the need for complex tooling and moulds.

Furthermore, 3D printing enables the consolidation of multiple parts into a single printed object, streamlining assembly and minimising waste. As a result, manufacturers can achieve higher efficiency and reduce material costs, leading to more sustainable and economically viable production processes.

3D printing can disrupt traditional supply chains by enabling localised manufacturing. With the readily available technology, products can be printed on-site or close to the point of consumption. This reduces shipping and logistics costs while decreasing lead times. By decentralising production, manufacturers can respond quickly to changing consumer demands, avoid disruptions caused by global crises, and reduce their carbon footprint by minimising long-distance transportation.

As we witness the impact of 3D printing in 2023, it becomes clear that this technology has transformed the manufacturing industry in multiple ways. From enhanced product development and customisation to cost reductions and localised production, 3D printing has opened up new horizons, empowering manufacturers to thrive in an increasingly competitive and dynamic market landscape

RetroCast 3D Printing provides end-to-end 3D Printing Services located here in Brisbane QLD. We can assist in the design, production, and testing of your project and its application. Call or email us today.

Conceptually having a tangible object can help you through the creative process. RetroCast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to RetroCast 3D Printing to explore your options

and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More