Getting Started

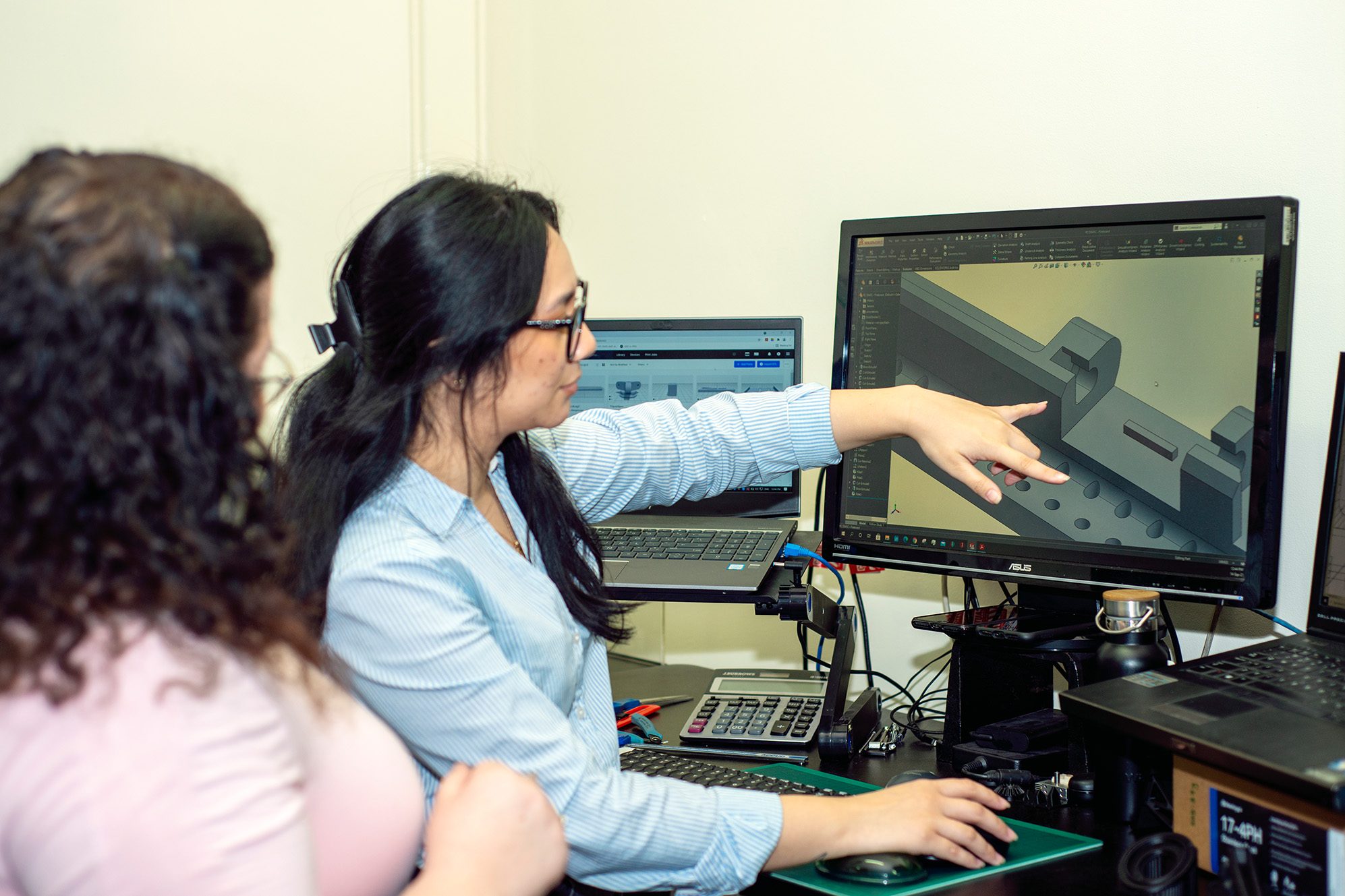

Design & Model your 3D Product - Make sure you determine the materials required based its required properties. Use the recommeded software to design your project - or talk to one of our Engineers about converting your sketch into a 3D Scan compatible with our 3D Slicing Software. Contact Our Team about Your Project >

Plastic, Carbon Fiber or Metal. See the details below to help you make your choice. See the list below >

Our team can help you get your project printed in as little a a couple of days. Talk to us about your project to get a quote send us an

email here.

3d Printing Materials

Talk to Our Engineers About Which Filament to Use For Your Project >

3d Printing TERMS

| 3D file / 3D model |

Three-dimensional object presented as a file, created either by a 3D modelling software or a 3D scanner |

| 3DP |

3-Dimensional Printing |

| ABS |

Acrylonitrile Butadiene Styrene - opaque thermoplastic and amorphous polymer |

| AM |

Additive Manufacturing, also known as 3D Printing |

| .amf |

Additive Manufacturing File |

| BJ |

Binder Jetting -3D Printing Technique. The binding liquid is deposited to join powder material together to form a 3D part |

| Bridge |

Terminology for sections of a print that are supported at both ends but not in the middle |

| Bowden tube |

Also called Bowden cable guides filament from the feeder to the print head on material extrusion printers |

| Build envelope |

This is the maximum volume the Printer can print and determines how large an object the Printer can build |

| Build plate |

Also known as a Bed and Platform - Surface or area of the 3D Printer on which parts are formed |

| CAD |

Computer-Aided Design |

| CAM |

Computer-Aided Manufacturing |

| CDLP |

Continuous Direct Light |

| CNC |

Computer Numerical Control |

| Control Interface |

Used for controlling the #D Printer, older Printer has an LCD Display, an SD Card slot or USB port |

| DED |

Direct Energy Deposition |

| DLP |

Direct Light Processing is part of the vat photopolymerization AM method where a photopolymer liquid resin is cured to make hard plastic

parts |

| DMD |

Direct Metal Deposition |

| DMLS |

Direct Metal Laser Sintering |

| DOD |

Drop-On-Demand |

| EBAM |

Electron Beam Additive Manufacture |

| EBM |

Electron Beam Melting |

| Extruder |

Filament is pushed through a Bowden tube to the hot end of the rotating gripping wheels known as the 3d printer Head. |

| FDM |

Acronym for Fused Deposition Modeling |

| FFF |

Acronym for Fused Filament Fabrication |

| Filament |

Used by FDM printers to melt plastic filament, typically made of either ABS or PLA |

| Fill / Infill |

Terminology to printing the interior structure of a 3D object. The interior is printed with a mesh type structure. The infill is expressed

as a percentage (e.g. 10% infill). |

| G-code |

G-code -A file format used to store information that 3D printers can interpret |

| GDP |

Gel Dispensing 3D Printing technology. Uses movement similar to FDM systems using UV sensitive material that hardens when exposed to UV

light |

| GF |

Glass-Filled |

| Hot end |

The material extrusion method, also known as additive manufacturing. Material extruders reach temperatures to melt plastic (hot end) |

| Kapton tape |

Heat-resistant polyimide adhesive tape. Used in material extrusion printers to cover the surface of the print bed to prevent it from warping |

| LCM |

Lithography-based Ceramic Manufacturing is a process for the additive manufacturing of high-performance ceramics |

| LENS |

Laser Engineered Net Shape |

| LMD |

Laser Metal Deposition, a printing process that casts and fuses metal with a laser beam |

| LOM |

Laminated Object Manufacturing |

| LS |

Laser Sintering |

| Material Extrusion |

A continuous filament of thermoplastic. Used to construct 3D parts. |

| Mesh |

Dividing a model into basic blocks or structures that are small |

| Micro |

Terminology to describe a unit of length equal to one-millionth of a meter |

| MJ |

Material Jetting |

| MJF |

Multi Jet Fusion |

| Nozzle |

Deposits melted plastic material. |

| NPJ |

NanoParticle Jetting |

| OBJ |

Object File |

| PA |

Polyamide |

| PBF |

Power Bed Fusion |

| PC |

Polycarbonate |

| Photopolymer |

Polymer material that changes its properties when exposed to light |

| PIM |

Plastic Injecting moulding |

| PLA |

Polylactic Acid – Biodegradable thermoplastic polymer made from plant starch. |

| PP |

Polypropylene |

| Print Head |

Typically, one extruder on it. On the top of the print head is a tube that feeds filament into the print head |

| PVA |

Polyvinyl Alcohol – Water-soluble filament used as support material in 3D Printing |

| RAFT |

Horizontal mesh of filament deposited directly onto the build platform. to minimize warping. |

| RE |

Reverse Engineering |

| RM |

Rapid Manufacturing |

| RP |

Rapid Prototyping |

| SLA |

Stereolithography Apparatus |

| SLICER |

Software used to convert the digital 3D file into a machine-readable code. The Slicer cuts the model into skinny horizontal layers called

slices and generates tool paths in the two-dimensional plane |

| SLS |

Selective Laser Sintering |

| Thermoplastic |

Material such as synthetic resin becomes plastic when heated above a specific temperature and hardens when cooled |

| TPU |

Thermoplastic Polyurethane |

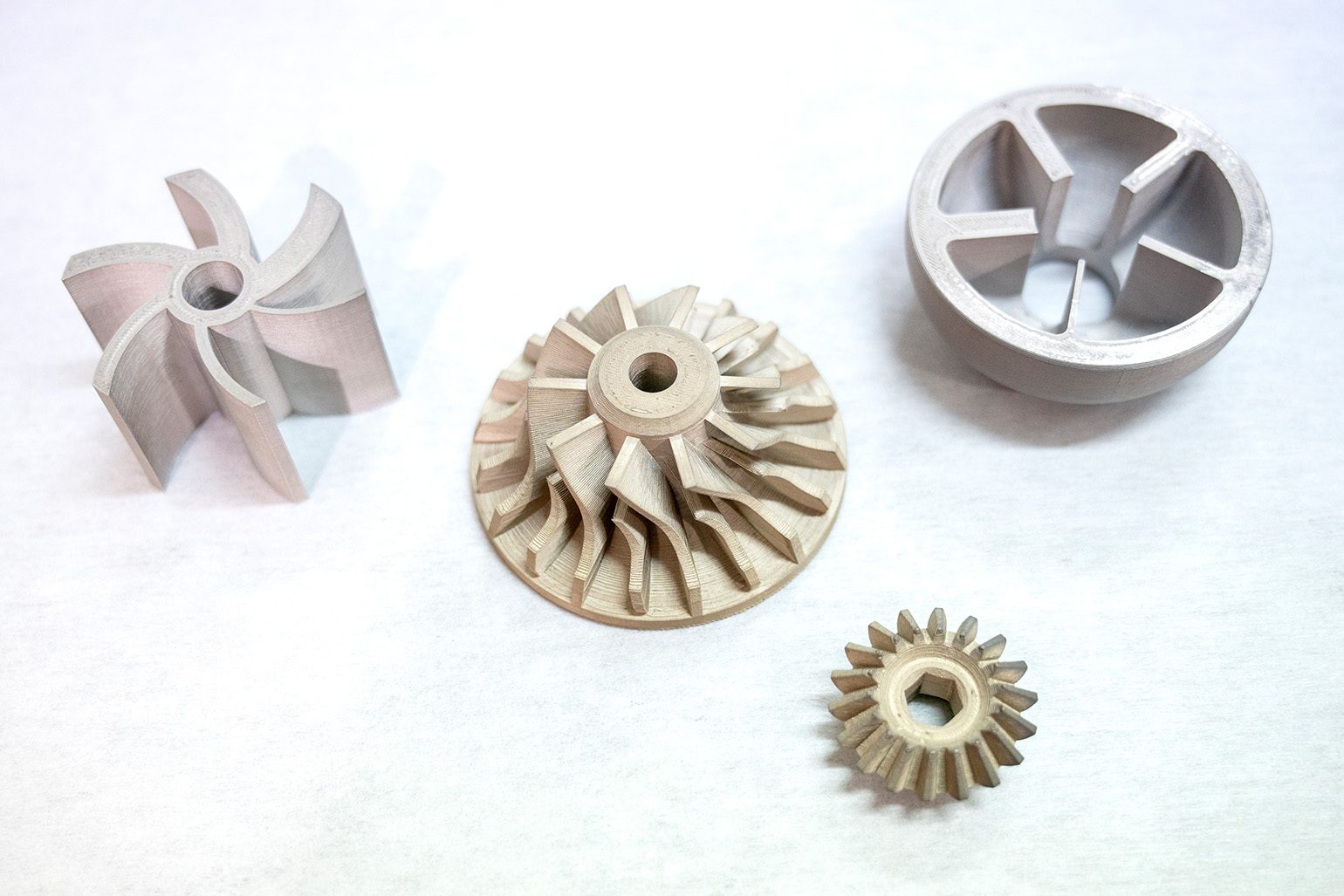

Conceptually having a tangible object can help you through the creative process. Retrocast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to Retrocast 3D Printing to explore your

options and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More