introDUCTION

You’ve probably seen some 3D printing ads or read about startups offering digital fabrication services. After all, the ability to print in three dimensions can accelerate product development, reduce costs and increase market penetration.

So why have so many companies started operating their 3D printing services? That’s because the value of a low-cost production solution that can quickly test new ideas and produce small batches of finished parts is now more apparent than ever before. This trend will only continue to accelerate.

Today, most manufacturers understand that investing in 3D Manufacturing Technology is now a necessity for success. However, not many understand why investing in manufacturing technology should be a top priority for any company’s growth strategy.

You can expect to see these results if you operate your own manufacturing services business. Keep reading to learn more about our reasoning behind starting our own manufacturing service business and how we’re seeing early results after just two months of operating as a 3D Printing Manufacturer.

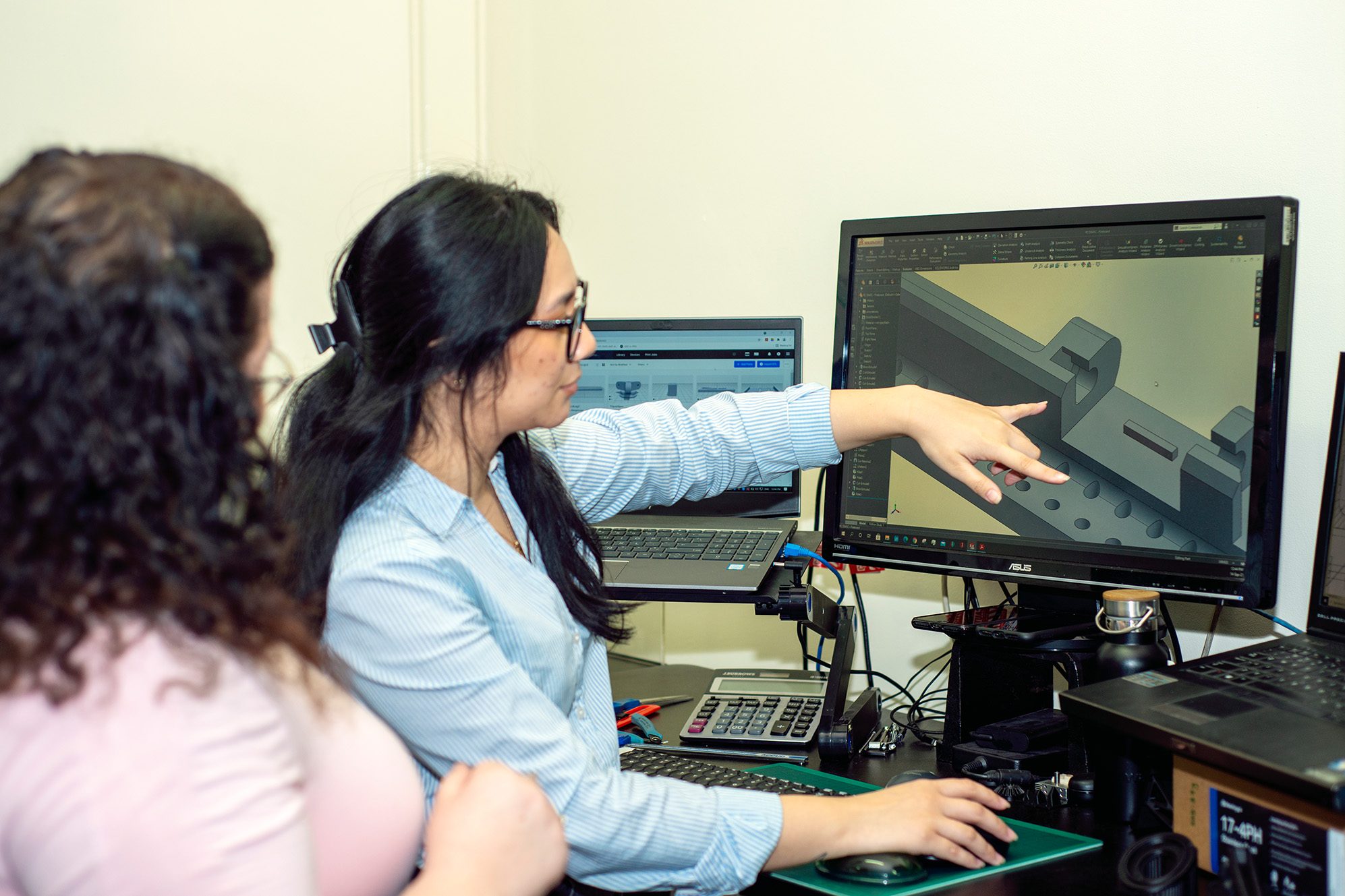

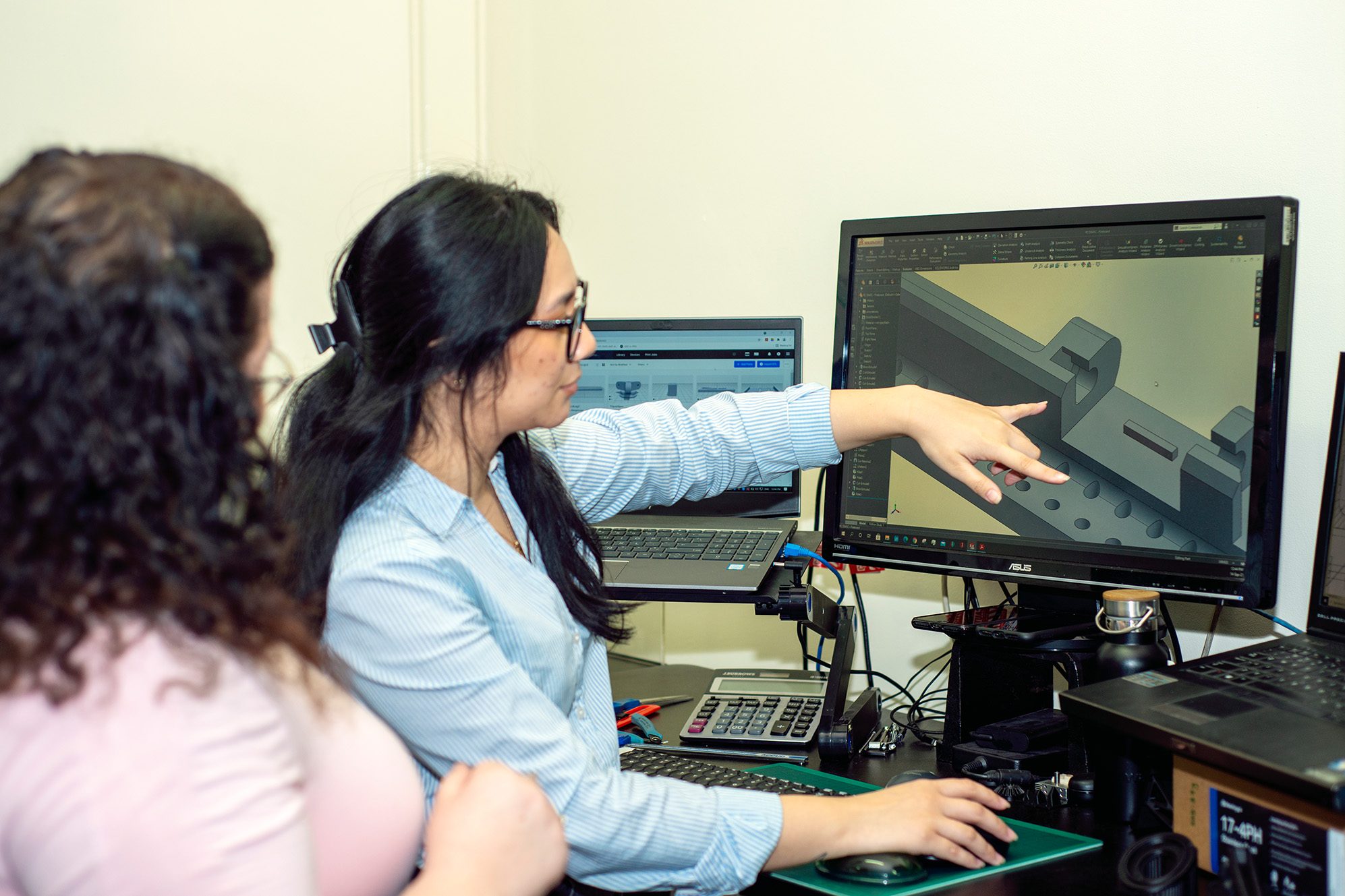

At Retrocast 3D Printing we take pride in our processes and dedication to providing high quality products and maintaining thorough testing processes to ensure customer satisfaction and premium product and service delivery.

explained

3D printing is the process of creating three-dimensional objects from a digital representation using additive manufacturing techniques.

There are two types of 3D printing:

As a digital fabrication service, we provide customers with a low-cost way to quickly test new ideas and produce small batches of finished parts.

It’s also important to note that our goal is not just to be a 3D printing service but also to provide solutions for other processes that can benefit from 3D technology, like ergonomics or functional prototyping.

Learn More >

It also helps you determine the demand for your products by expanding the number of customers who can purchase them and reducing the risk associated with manufacturing new designs and products in-house.

Another advantage of manufacturing technology is that it gives manufacturers a low-cost way to test new ideas and produce small batches of finished parts. This allows manufacturers to quickly expand their business by identifying a need for a new product, testing out different design variations, and then producing the final version in larger quantities.

Finally, manufacturing technology lets manufacturers create a brand by producing products that embody their company’s aesthetic or personality.

As such, 3D Manufacturing Technology makes it easier for companies to establish an authoritative presence and attract potential customers interested in what they offer.

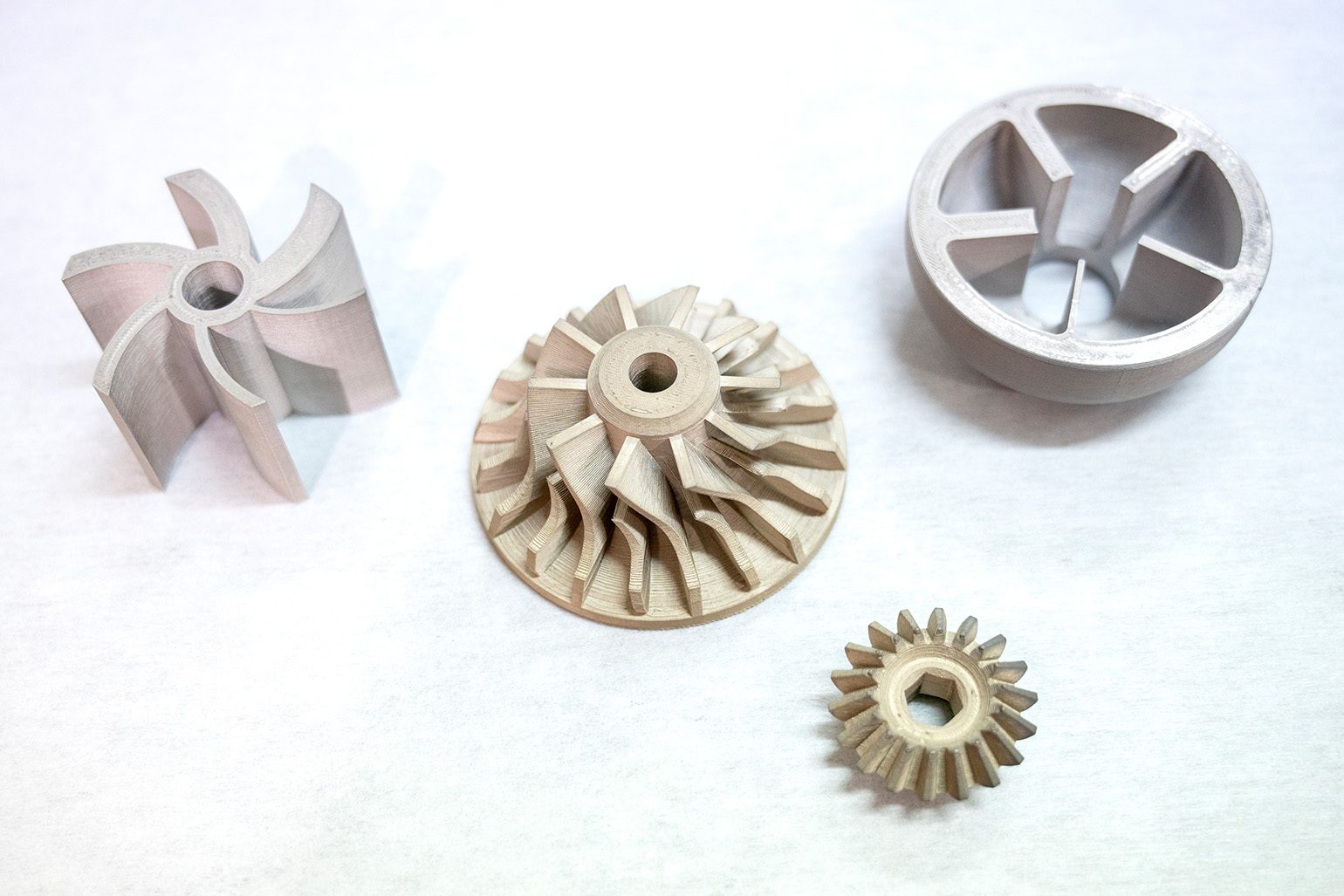

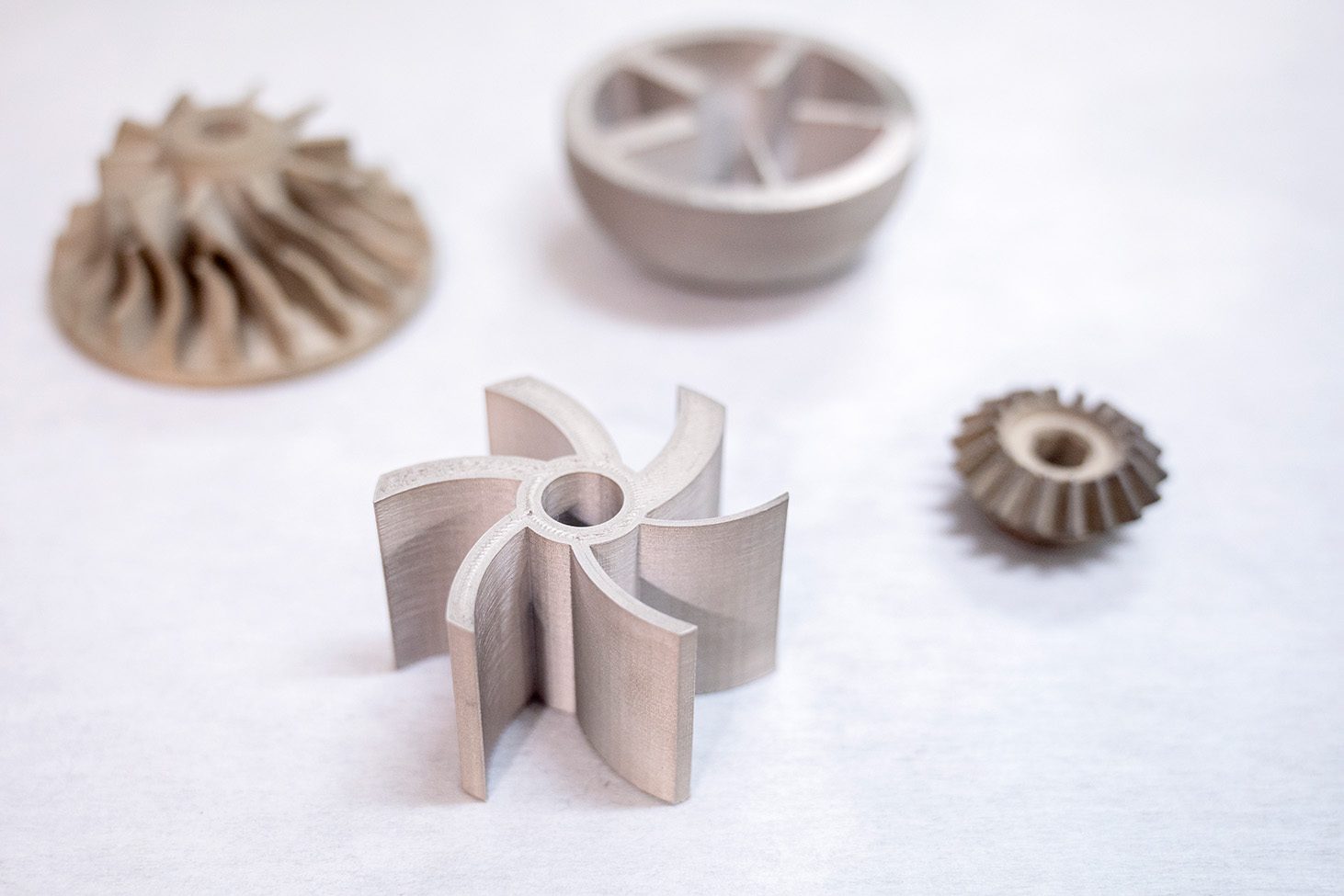

Conceptually having a tangible object can help you through the creative process. Retrocast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to Retrocast 3D Printing to explore your

options and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More

Manufacturing & Innovation

The first reason for investing in manufacturing technology is cost savings. When you start your 3D printing project, you have complete control over your design process and product materials.

For example, if you could save up to 80% by using a low-cost production solution to test new products, it would be irresponsible not to take advantage of this opportunity.

Another reason manufacturers should consider outsourcing their manufacturing needs is the ability to reduce costs while increasing productivity with faster delivery of the project.

Other benefits include the speed of production and quality control, which will give you greater flexibility while speeding up your

time-to-market. If a company wants to stay competitive in today’s competitive market, investing in the latest technology is necessary for

success.

Contact Us Today >

Speak to an engineer today