Getting Started

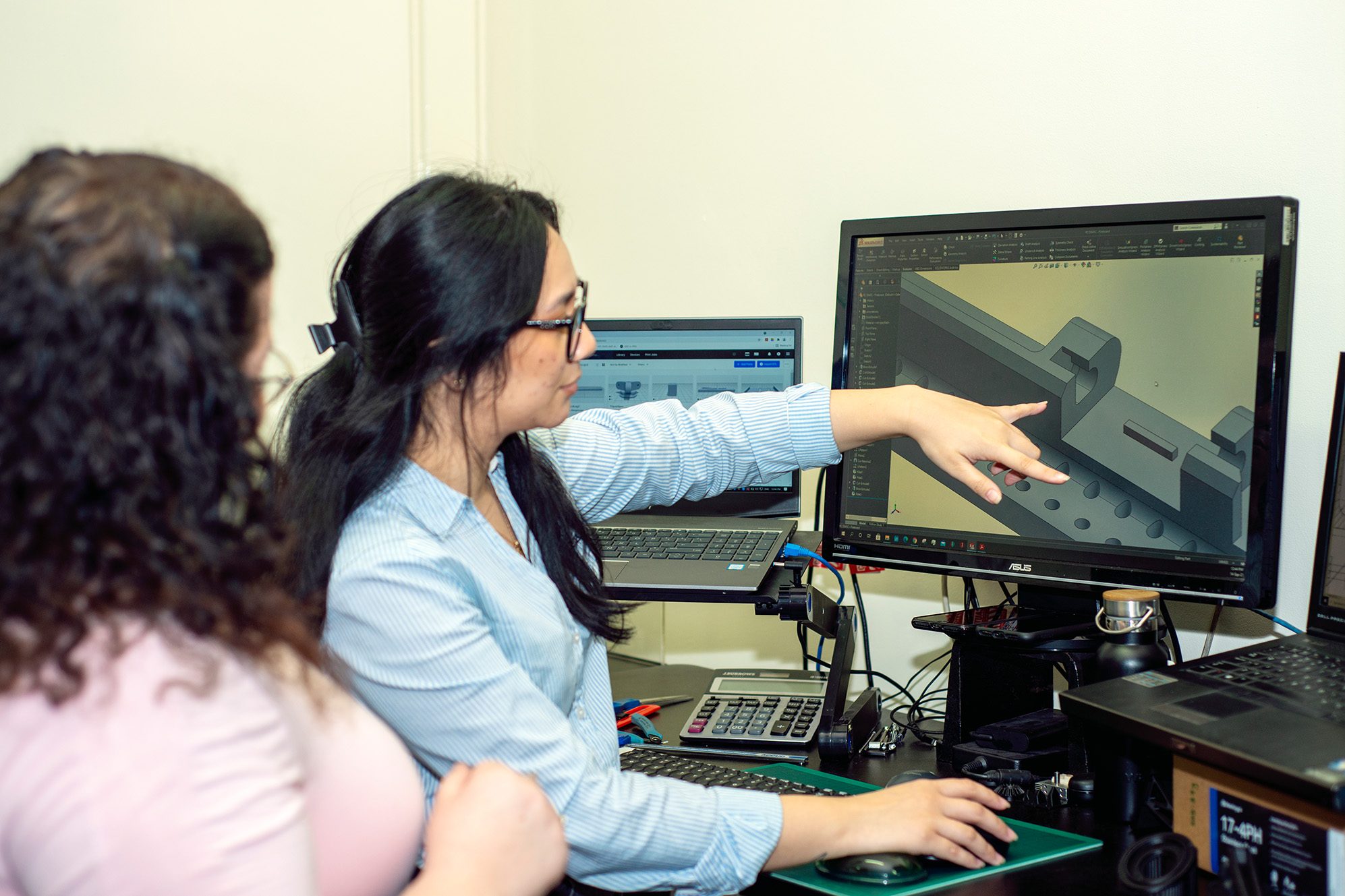

Design & Model your 3D Product - Make sure you determine the materials required based its required properties. Use the recommeded

software to design your project - or talk to one of our Engineers about converting your sketch into a 3D Scan compatible with our 3D

Slicing Software. Contact Our Team about Your Project >

Plastic, Carbon Fiber or Metal. See the details below to help you make your choice. See

the list below >

Our team can help you get your project printed in as little a a couple of days. Talk to us about your project to get a quote send us an email here.

3d Printing for Beginners

The 3D Printer that we use is a Raise3D Pro2 Printer. Dual extruders enable the 3D printer to produce objects with multiple filaments, such as a water-soluble 3D printing material, and multiple colors. Performance capability of high resolution for manufacturing and rapid-prototyping projects of varying sizes within an allocated budget.

Raise3D Pro2 - materials for plastic 3D Printing - PLA, ABS, ASA, PETG.

Raise 3D Pro2 works with ideaMaker which is a free 3D Slicing software, preparing your design for the printer

Taking A Closer

Composite 3D Printing technology that we use is a Markforged X7 Printer, that prints in Carbon Fiber. The X7 3D prints Continuous Carbon Fiber reinforced parts in a matter of hours. These parts very strong, and they are capable of replacing machined aluminum. It's functionality includes flame resistance, chemical resistence, and absorbs energy output with high resolution and provides draft parts.

The Markforged X7 uses Nylon Carbon Fiber Hybrid internal continuous fiber.

Eiger Cloud - 3D Slicing Software

Taking A Closer look at

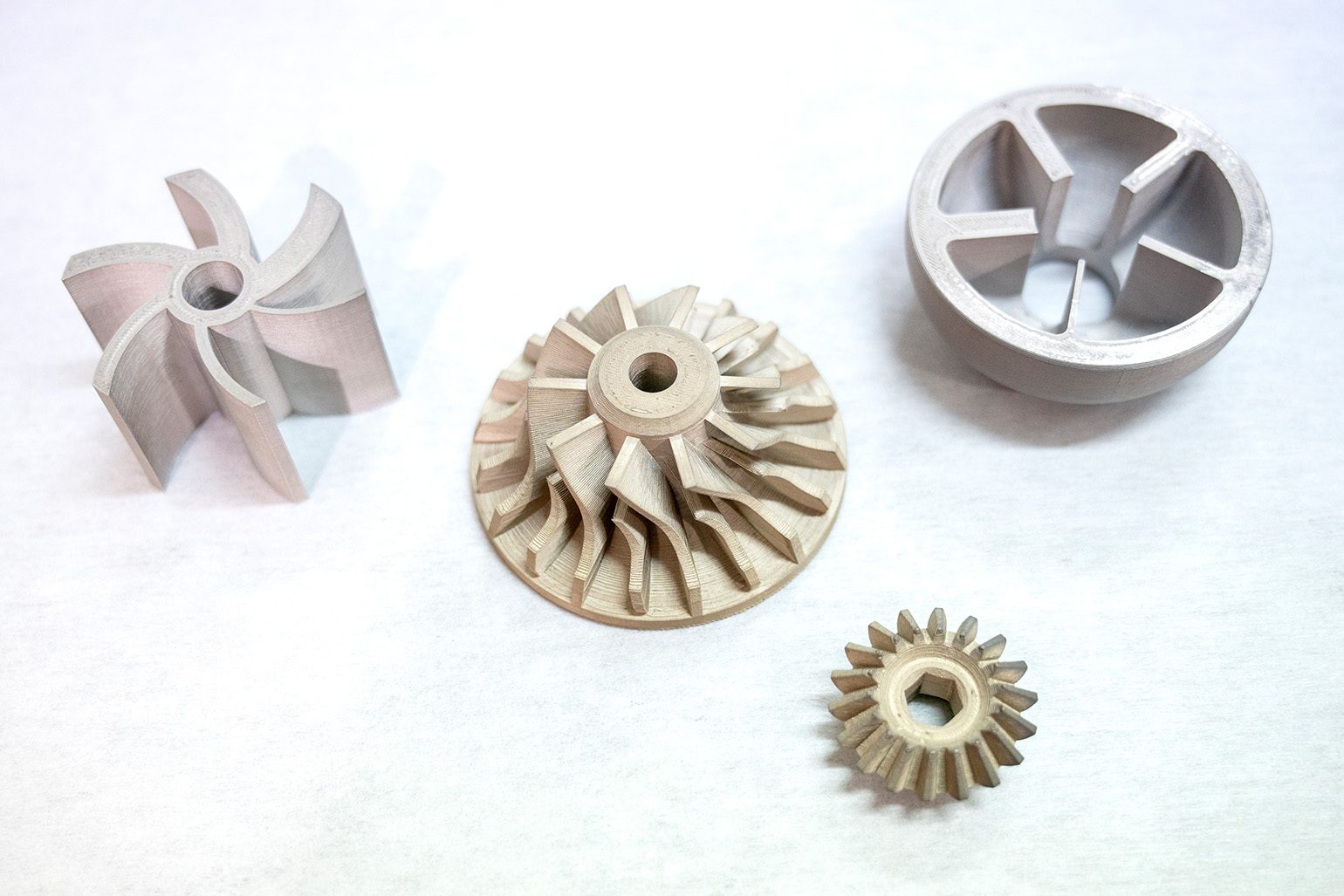

The 3D Printer that we use is a Markforged Metal X Printer. This is an end-to-end 3D Printing Solution that is suitable for functional parts - composed of metal

Eiger Cloud - 3D Slicing Software

Conceptually having a tangible object can help you through the creative process. Retrocast 3D Printing will construct concept models that

mimic the appearance of production-run parts.

Learn More

Display your design and relay the marketability of

your product. Create a market for your product before production. Send your 3D Concept to Retrocast 3D Printing to explore your

options and get a quote.

Get a Quote

We can test your new product is doable prior to full production. Rapid prototyping services allows us to test the form, fit, and function of your prototype.

Ensuring durability and quality.

Discover More